Thiess Degrémont has provided a glimpse into the operations and control centre of the now-completed $3.5 billion Victorian desalination plant.

The firm said in a statement that the project had passed "the final contractual milestone of reliability testing finalisation".

A maintenance workforce of 52 permanent staff will look after the plant now that construction and testing is complete.

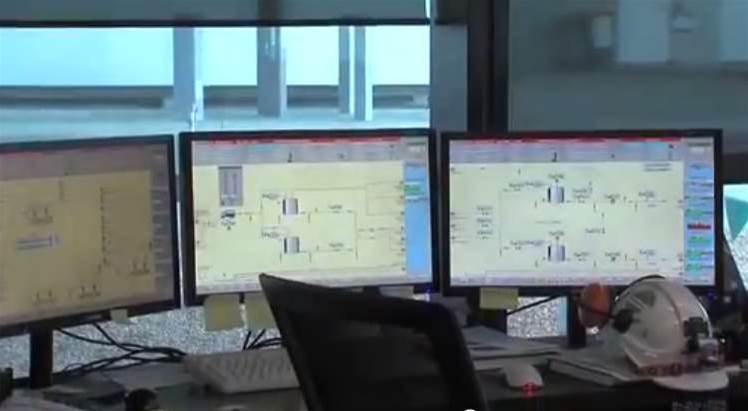

An accompanying video shows the inside of the plant's control centre.

"The quality of water we have to produce is an extremely high quality water, which requires a very very detailed level of control and monitoring, and it all has to be real time," operations manager Mike Jury said.

Engineering & commissioning director Omar Shahin said the plant consisted of "somewhere in the region of 570 pumps, a little over 18,000 valves, [and] a little over 8000 instruments".

Shahin said one of the commissioning challenges was making sure "that everything is communicating with each other".

The plant uses a Siemens PCS7 process control system that is visible in several frames of the video.

AquaSure — the state government's private-sector partner for the project — has previously noted that the plant will use fibre optic cables to "provide important monitoring information" on infrastructure. AquaSure contracted works to the Thiess joint venture.

The video provides some statistics on cable connections, referring to around 100 different cable types, including fibre optics for the control system.

In total, around 17,000 pieces of kit across the site share 75,000 cable connections, according to Thiess.

_(33).jpg&h=140&w=231&c=1&s=0)

.png&h=140&w=231&c=1&s=0)

_(36).jpg&h=140&w=231&c=1&s=0)

iTnews Executive Retreat - Security Leaders Edition

iTnews Executive Retreat - Security Leaders Edition

iTnews Cloud Covered Breakfast Summit

iTnews Cloud Covered Breakfast Summit

Melbourne Cloud & Datacenter Convention 2026

Melbourne Cloud & Datacenter Convention 2026

The 2026 iAwards

The 2026 iAwards

_(1).jpg&h=140&w=231&c=1&s=0)