Faster and larger storage for enterprise and consumer applications is on the menu next year after Samsung announced that it has started mass production of three dimensional flash memory.

Current planar Flash memory technology is starting to hit the limits of scalability, as shrinking lithography to 10 nanometres and the use of floating gates is causing interference between cells, leading to reliability issues.

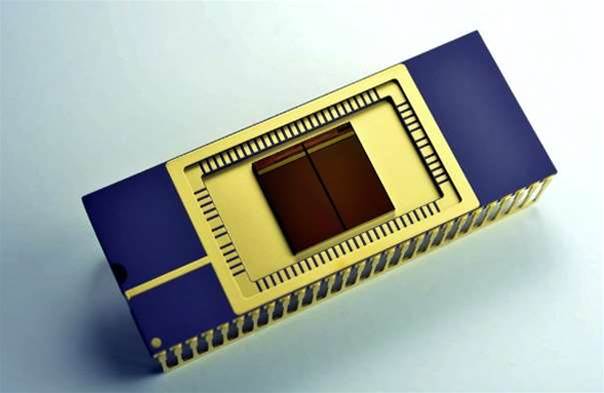

The new Flash memory features a Samsung-developed process with interconnects for as many as 24 vertical cell layers. This uses etching technology to connect the layers by punching holes through them.

By using the proprietary interconnects and Charge Trap Flash technology — which has been known since the late 1960s but wasn't commercially utilised until 2002 when AMD and Fujitsu started mass producing chips with the feature — Samsung said it has been able to achieve twice the scalability of 20 nanometre Flash with its new memory chips.

Thanks to the stacked chips, devices will be able to have much larger storage capacity than is possible today. Samsung will make the initial product range with capacities from 128 gigabytes up to 1 terabyte.

The chips will go into solid state drives (SSDs) and inside mobile devices, Samsung said.

Further, the 3D stacked chips are claimed by Samsung to be twice as fast for writes as the current generation of Flash memory, and between twice and ten times as durable.

The Korean company has been working on three dimensionally stacked NAND Flash memory for several years, presenting the technology in 2006 to the IEEE.

Samsung is facing competition in the non-volatile memory market however, as new technologies emerge.

Yesterday, a Californian start up, Crossbar, unveiled its Resistive Random Access Memory (RRAM) technology that promises to be twenty times as fast as NAND Flash.

RRAM is also three dimensional, using three vertical layers, and uses less power than current Flash memory, which would help extend device battery life.

While not yet commercially available, the company told VentureBeat that the technology is easy to manufacture in existing plants, and this has already been done in Taiwan.

_(20).jpg&h=140&w=231&c=1&s=0)

_(28).jpg&h=140&w=231&c=1&s=0)

_(23).jpg&h=140&w=231&c=1&s=0)

iTnews Benchmark Awards 2026

iTnews Benchmark Awards 2026

iTnews Executive Retreat - Security Leaders Edition

iTnews Executive Retreat - Security Leaders Edition

iTnews Cloud Covered Breakfast Summit

iTnews Cloud Covered Breakfast Summit

The 2026 iAwards

The 2026 iAwards

_(1).jpg&h=140&w=231&c=1&s=0)